Optimal Energy Control Modelling of a Vertical Shaft ...

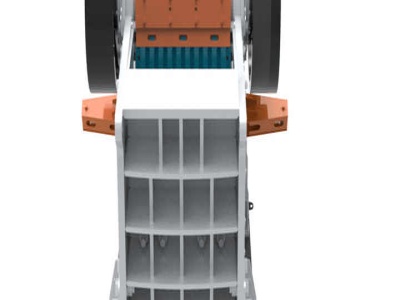

Vertical shaft impact (VSI) crushers are usually used in tertiary crushing station of both aggregate and mining industries for crushing of hard rock material or ores when a product material with cubical shape and large amount of fines is required [1, 2]. VSI crusher has .