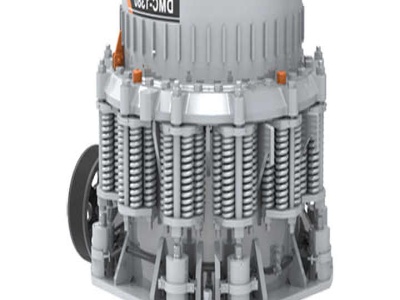

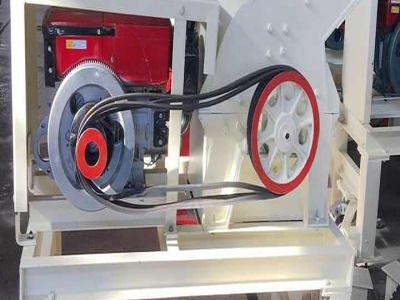

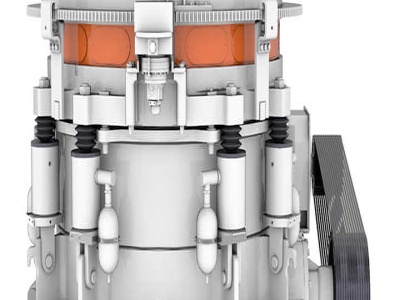

mining equipment mining machine iron ore magnetic separator,

Iron ore mining equipment / mining machine / new magnetic separator REQUEST A QUOTE Support: +86 400 8855 646 : RY series iron ore magnetic separator is widely used in lowgrade iron ore beneficiating With stable digital sensor, strong impules magetic fields and autoelectric valve system, it can produce high grade iron ore