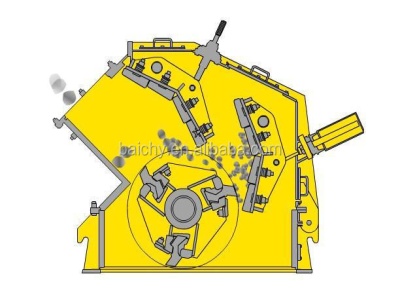

Gyratory Crushers

Diamond supplies Trio Gyratory Crushers. These crushers are a proven first stage of compression crushing for Large Mines and Quarries. Mined ore or quarried rock can processed down to a size suitable for the secondary crushers. Trio® TG Series Primary Gyratory crushers combine latest design together with innovative engineering, advanced technology and manufactureing [.]