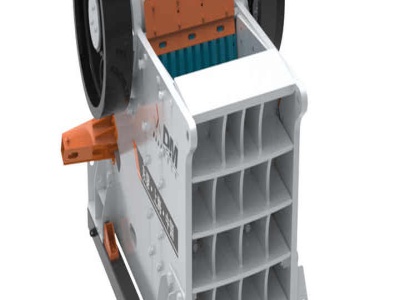

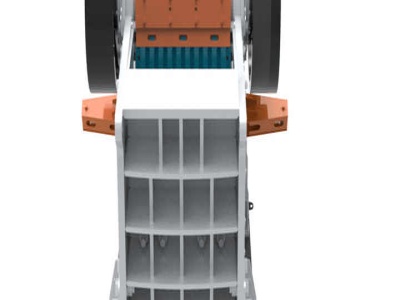

® C150™ JAW CRUSHER | Pilot Crushtec

Nordberg® C150™ jaw crusher offers outstanding performance in terms of operating lifetime and its ability to crush large feed material to required product sizes at high capacity rates. An extended feed opening not only accepts material up to one meter (40"), but also easily breaks it by the increased stroke at the top of the cavity.