OPPDry: Materials Handling Facilities | Oil Sands Magazine

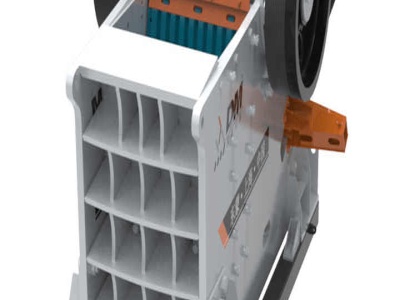

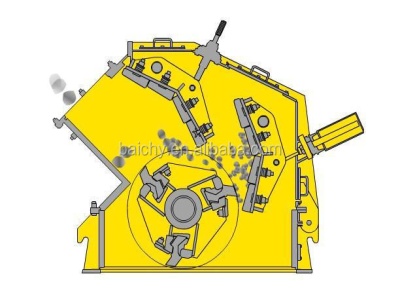

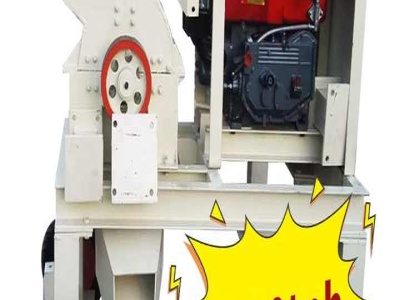

· Conveyors installed underneath the crushers transport the loose oil sands to the downstream storage pile or surge bin. The hopper, apron feeder and crusher is often loed in one single structure, tucked into a retaining wall inside the crusher pit.