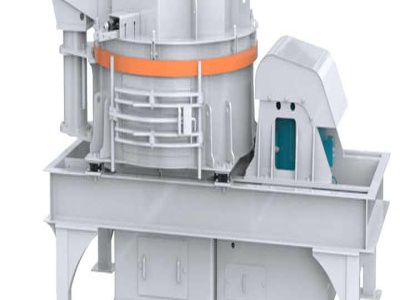

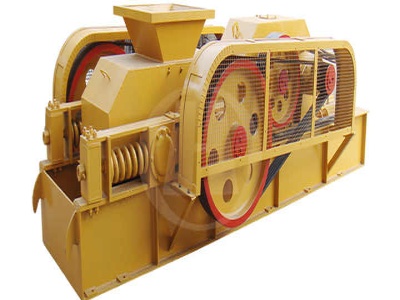

Ball Milling

Ball milling, a shearforce dominant process where the particle size goes on reducing by impact and attrition mainly consists of metallic balls (generally Zirconia (ZrO 2) or steel balls), acting as grinding media and rotating shell to create centrifugal this process, graphite (precursor) was breakdown by randomly striking with grinding media in the rotating shell to create shear and ...

![[ process ball milling vs rod ]](/um7yinb/531.jpg)

![[ process ball milling vs rod ]](/um7yinb/939.jpg)