Mining | Replacement wear parts for crushers, sizers ...

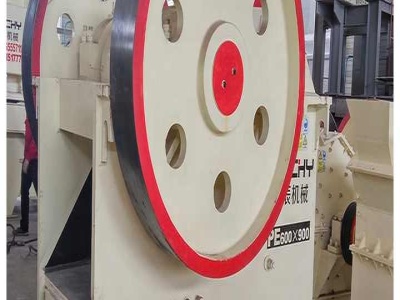

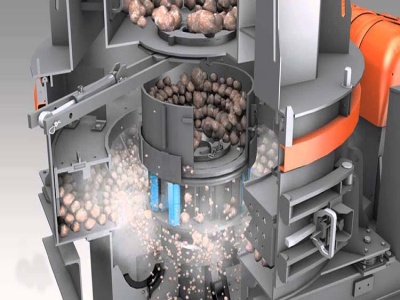

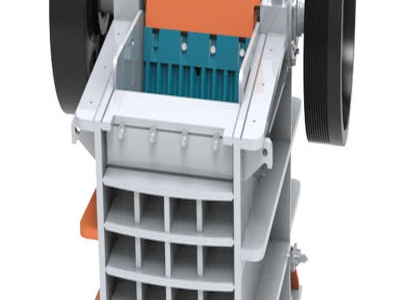

Unicast wear parts address the full range of mining industry appliions, from crushing, screening, feeding, grinding, power transmission and slurry transport. Our mining industry products include parts for gyratory, jaw, roll and cone crushers, feeders, SAG ball mills, mining valves, roll crushers, sizers, and grizzlies.