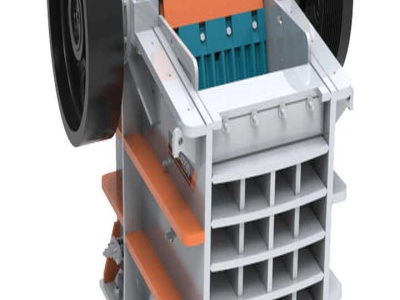

Osborn double roll crushers increasingly chosen for SA coal .

15/02/2016 · Osborn, the local manufacturer of crushing and screening equipment, reported that its locally manufactured double roll crushers are proving their mettle in the tough coal industry, where they are increasingly being chosen for their low fines generation.. Osborn 3054 Double Roll Crusher working at a coal operation near Lephalale. This is according to Elandsfonteinbased Osborn product sales ...