coal mill operational problems

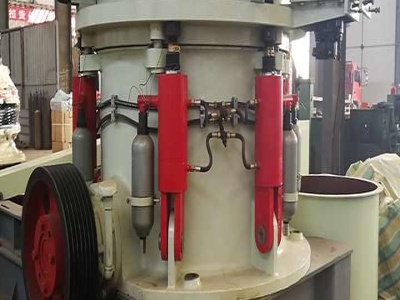

coal mill operational problems grinding mill for line upto 2 microns. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, .