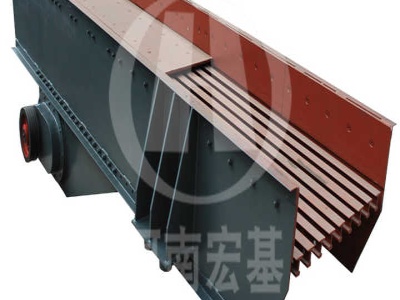

Cement Crusher – Crusher In Cement Plant | AGICO Cement

Raw materials of the cement plant are mostly from openpit mines, and the ore size of large mines can reach In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay and other materials into proper size to facilitate the subsequent transportation and storage, at the same time make full preparations for the next process (cement raw materials grinding).