Roller Mills by SIEBTECHNIK TEMA. Crushing milling ...

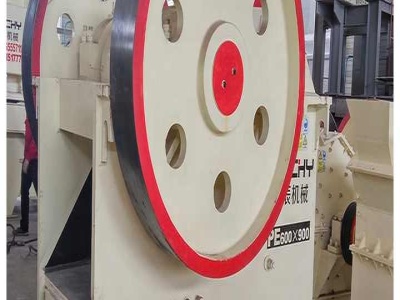

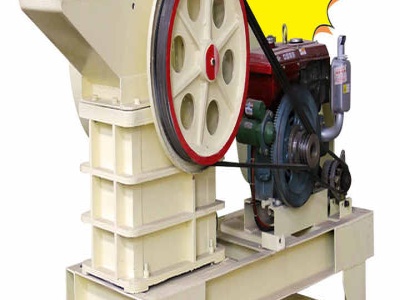

With the singleroller mills, brittle, soft to mediumhard materials can be reduced in size with a reduction ratio of approx. 1:5 to 1:5. The stepped arrangement of the crushing jaws on the crushing wall enables any material rolling off being minimised, so that, compared to .