Mechanical Performance of Concrete Made with Recycled ...

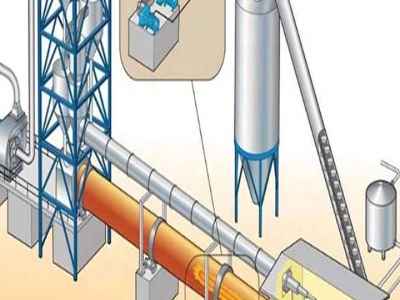

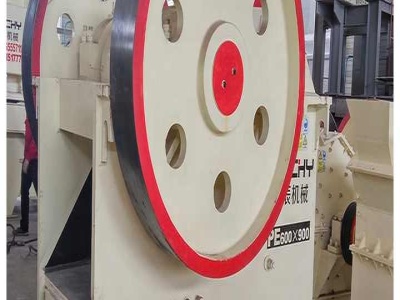

15/09/2020 · This research aims at analysing the mechanical performance of concrete with recycled aggregates from concrete pavements. First, the characteristics of various natural and recycled aggregates used in the concrete were thoroughly analysed. The composition of the recycled aggregates was determined and several physical and chemical tests of the aggregates were .