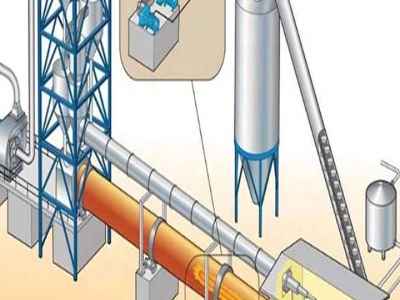

process flow for producing titanium dio ide from ilmenite

Titanium Dioxide IARC Publiions . 13 Mar 2017 ... made in processing of ilmenite and rutile ores for the extraction of TiCl4. It was aimed to ... This is dependent on the sought goal which is either to produce a pure titanium dioxide for ... The flow diagram of .