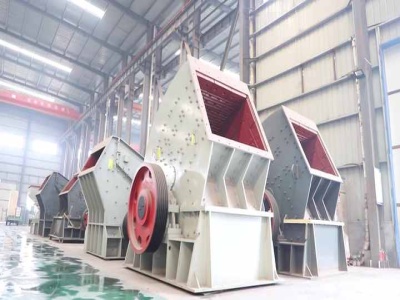

Crushing Screening Plant Design Factors

· Crushing Plant Design and Layout ConsiderationsCrushing Circuit "A'' shows a small simple layout for use in mills up to 100 tons. In order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day with a very simple arrangement; using a stationary or vibrating grizzly ahead of .