What are the Major Systems of the Mobile Crushing Station ...

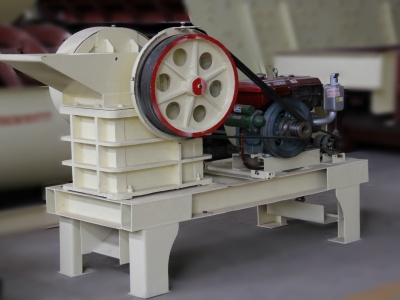

20/05/2021 · The mobile crushing station is a mobile production line that integrates a feeder, a crusher, a screening system, a debris sorting device and a conveyor, and is equipped with a walking mechanism. A complete set of mobile crushing station must be smooth in the whole line, matched in output, and meet the production needs with the lowest ...