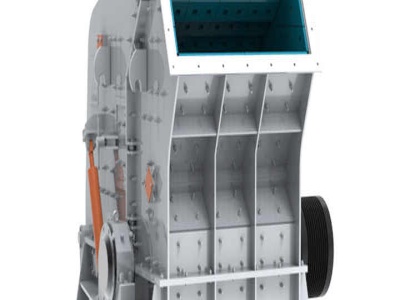

Perfecting the Performance of Secondary Crushers | E MJ

Ideally, the deck on the scalping screen should have a cut point equal to the closed side setting (CSS) of the crusher. The feed size to a secondary crusher is typically in the range of 50 mm to 250 mm (up to 300 mm). If the capacity is higher, the acceptable feed size gets larger. After crushing, the product is in the range of 060 mm (75 mm ...