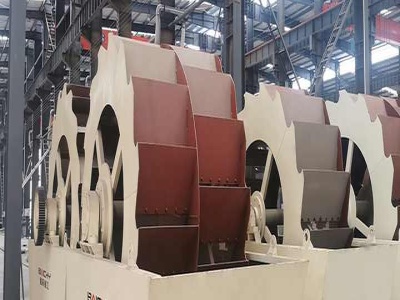

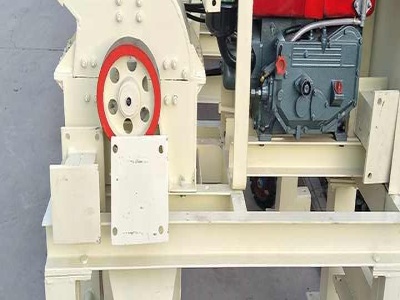

ball milling of slag design

Slag Ball Mill By Zhengzhou Unique of slag design ball mill . combination continuous ball mill grinding of sand and . Grinding Mill Design Ball the ball mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding. The Steel Head Rod Mill .get price.