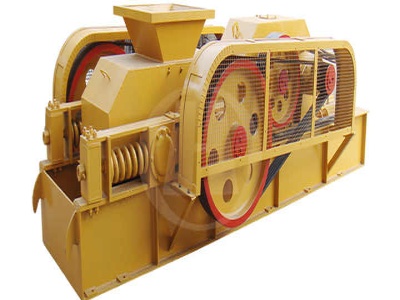

crusher Archives

But even boulders small enough to be processed by the primary jaw crusher can cause problems as breaking down large rocks requires a great deal of energy and can result in power spikes, slower production rates, and wear and tear of the crusher liner, Motion Metrics says. Even brief crusher delays can have massive effects over time. "For example, one of our customers is a large copper mine in ...