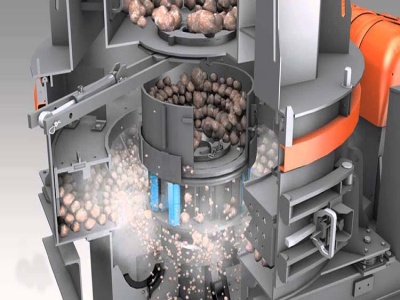

Rock Crusher (Railcraft)

The Rock Crusher is a multiblock structure added by machine is used to process various items and blocks. This machine runs off of Redstone Flux (RF), using 16,000 RF/use, and takes up to 160 RF/t. At full power, an operation takes seconds (as there is .