Colored Silica Quartz Sand, Natural Color / Artificial ...

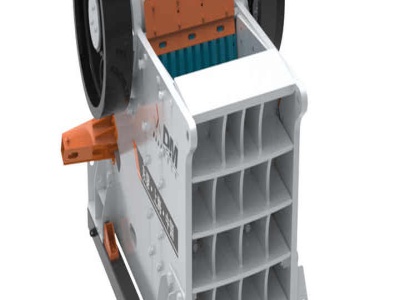

Common Quartz Sand Our Common Quartz Sand is generally made of natural quartz ore, through crushing, washing, drying, and secondary screening process. The main composition of silica reaches 98% above, the mohs hardness of quartz sand which we produced can reach 7 degrees, Being with high mechanical strength, stable chemical performance, strong ...