Construction, Working and ...

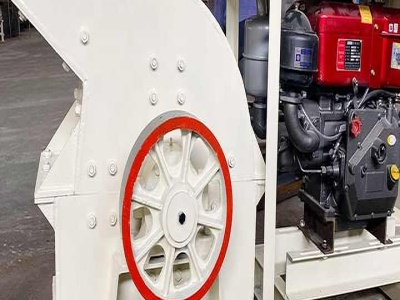

5 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials In a nonreversible hammer mill with screen bars, shown in above figure, material is broken first by impact between hammers and breaker plates and then by .