Ujjain tooth roll crusher processing river pebble

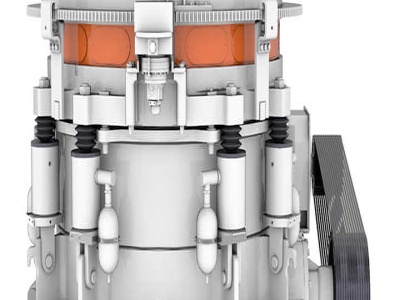

River Pebble Crushing Process River Pebble Crusher. River Pebble Cone Crusher In river pebble crushing plant cone crusher is generally used as secondary crushing equipment for crushing the river pebble into required sizes for further processing or for end use SBM cone crusher has large capacity which can even reach to 1000 tons per hour. Oline Chat