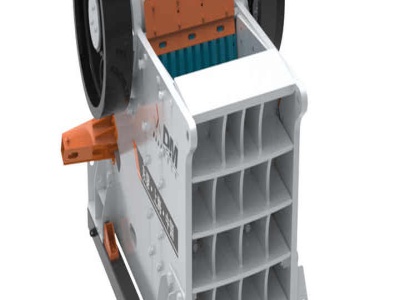

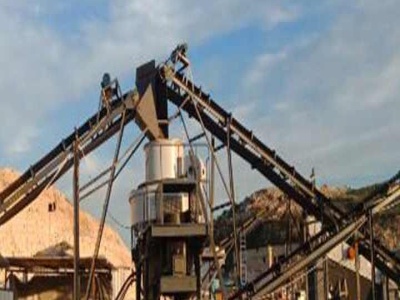

Crushers

Crushers are machines used to reduce the size of rocks, stones and ore. They are often utilized in aggregates production, construction material recycling and in mining operations. Our offering covers different gyratory crushers, jaw crushers, cone crushers and impact crushers – optimized for any size reduction need. Offering.