coal crushers sizes

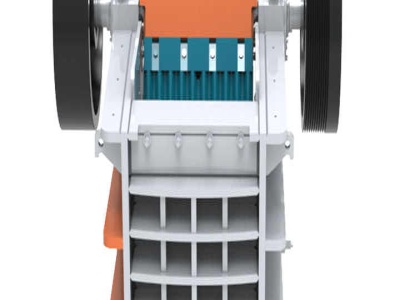

coal crusher for coal size mmschorniskaminstudio Coal Crusher 21 Mm Size 1 Kg Of 6Mm Size Coal. For different size ranges of the feed particles the outlet widths of the jaw crusher and the parallel roller crusher were adjusted as 3 4 6 9 mm and 1 mm respectively. the coal particles fed into the cfb boilers are usually in the size range of 0–8 mm covered by the product size in the tests.