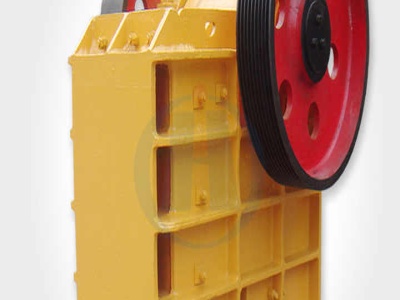

Apron Feeders

An apron feeder is a reliable feeding method for when the material to be conveyed is lumpy, abrasive, heavy, high temperature, or where a feeding solution more robust than a traditional belt feeder is required. Apron feeders are designed to feed material at a desired volumetric rate to downstream equipment and convey material on a series of ...