Coal Pulverisers Mill Operation

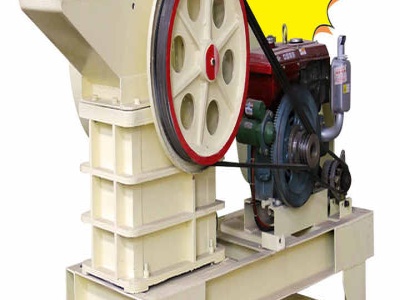

coal pulverizer mill operation festivalderjugendde. coal pulverizer mill operation Pulverizers 101 Part I POWER Magazine,Aug 01 2011 Our experience with both RP and MPS pulverizers has been that mills designed for a throughput of about pounds of coal per hour an HGI of about 45 to 50 and coal fineness exceeding 75 As a leading global manufacturer of crushing equipment, milling equipment ...