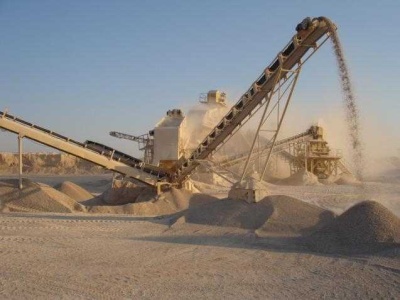

Crushers House

High capacity and large crushing ratio. Cone Crusher. Built using "Tried and True" Technology Manual and Hydraulic adjustment and locking on 3Hydraulic locking and adjustment on 41/4 and larger long life and low operating and maintenance cost built info every crusher.