UPDATE ON MOUNT PEAKE FRONTEND ENGINEERING AND .

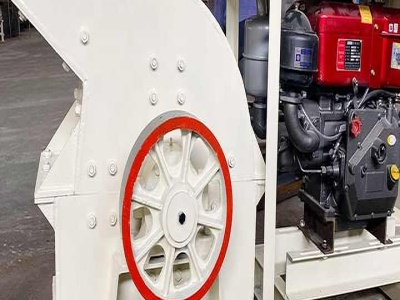

• The Beneficiation Plant has been designed to process up to Mtpa of titanomagnetite ore and produce up to Mtpa of magnetite concentrate. • The magnetite concentrate produced by the Beneficiation Plant is planned to be transported to the DPF for processing into vanadium pentoxide, titanium pigment and iron oxide fines for global export.