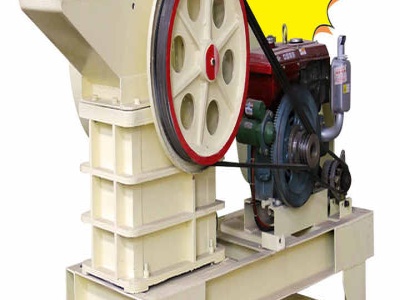

used sand and gravel plants

Used For Gravel Crushing Plant kavijverbeek. Aug 25 2016 183 Used Sand And Gravel Plants Rock Crusher Equipment Used Sand And Gravel Plants ZME is a leading global manufacturer of crushing and used mobile gravel crushing plant used mobile gravel crushing plant Used Mobile Crusher for Sale mobile crusher plant Used Mobile Crusher for Sale 700 Views second hand mobile stone crusher