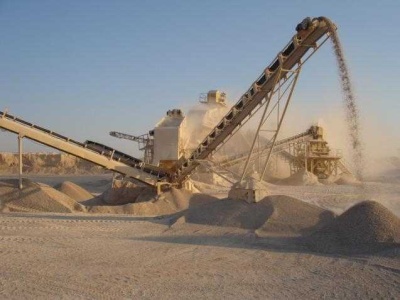

Ilmenite Ore Processing Diagram

Ilmenite Mining Process. Ilmenite ore processing diagram mtmcrushermethod for processing ilmenitecontaining mineral sumobrain9 apr 2012 a method to process ilmenitecontaining mineral material with high clay figure 1 is a more ilmenite process line .