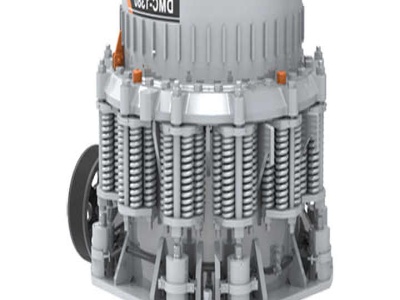

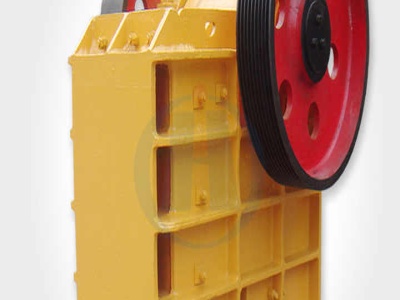

Power Plant Desulphurization And Milling Equipment

Capacity 20th vertical mill 200mesh limestone powder production for thermal power plant desulfurization line introduction Milling machine configuration VM1500M vertical mill host power 280KW Finished size 200 mesh D80 Production capacity 1820t h Customer case a thermal power plant 600MW units more than 10 units the use of more. 4015