How to configure a stone crushing plant

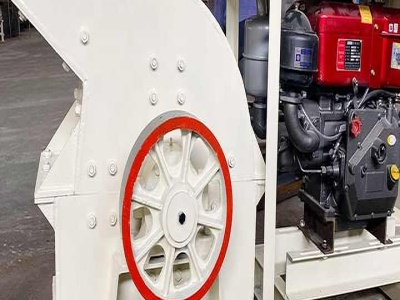

The main equipment is: vibrating feeder + small hammer type stone crusher + vibrating screen. performance characteristics of stone quarry crusher plant 1. The quarry cruser plant is highly automated. Except for the startup, shutdown and daily maintenance of the equipment, the complete production line almost does not need manual operation. 2.