Iron oxide in silica sand | Rigaku Global Website

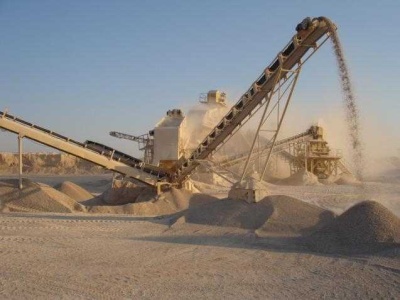

One of the major uses of silica sand is to make glass, and in particular glass bottles. The iron content is one of the major factors that affects the color of the glass. Low iron sands are used to produce clear glass for bottles, while sand with higher iron content is used to make amber glass bottles. Thus, both at the quarry site and in the manufacturing process, monitoring the iron content ...