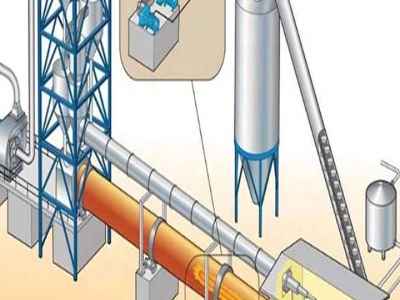

Ball mill

10/05/2019 · The rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the ball mill machine. The larger the diameter is, the slower the rotation is. If the peripheral speed of the ball grinding mill is too great, it begins to act like a centrifuge and the balls do not fall back, but stay on the perimeter of the mill. ...