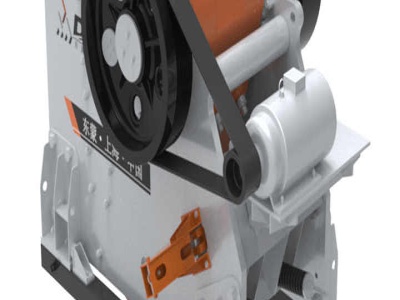

Cold Rolling Mill – Eonmetall

Cold Rolling Mill. Advantages. Low Investment Cost – Extremely flexible productive solution for producing high quality variety gauges of cold roll Production Cost – Continuous RD of new roller material quality have tremendously improved the roller wear Inventory Cost