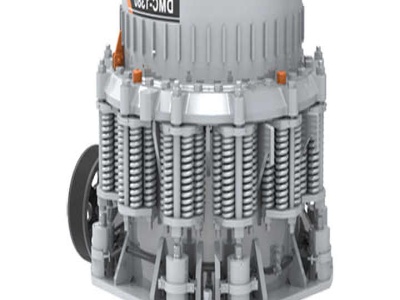

Alumina Ceramic Lined Ball Mill

Alumina Ceramic Lined Ball Mill, Find Complete Details about Alumina Ceramic Lined Ball Mill,Ce Ceramic Glaze Ball Mill Machine,Ceramic Balls For Ball Mill,Ball Mill For Ceramic Raw Material from Supplier or ManufacturerShicheng County Jinchuan Mineral Equipment Manufacturing Co., Ltd.