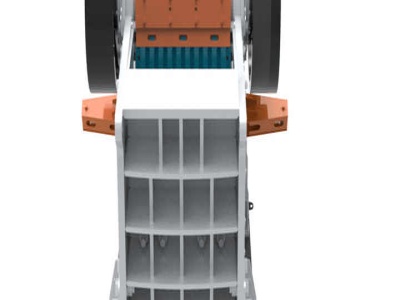

cone crusher cavity desing

The Crusher Cavity Of Cone Crusher Design Requirements. Cone crusher in the crushing cavity affects the performance of fractured equipment, reasonable design of crushing chamber is an important part of improves equipment performance. Let's look at the type of .