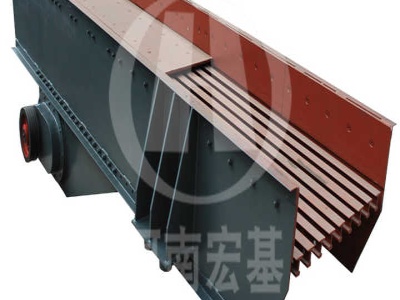

HGM80 Ultra Fine Grinder millgrinding mill/ultrafine mill ...

HGM80 Ultra Fine Grinder mill is mainly applied to noninflammable, nonexplosive and brittle materials with Mohs hardness under six. Such as calcite (calcite carbonate, calcium carbonate), chalk, limestone, dolomite, kaolin, gypsum, etc, totally more than 100 kinds of materials. Product fineness can be controlled between and