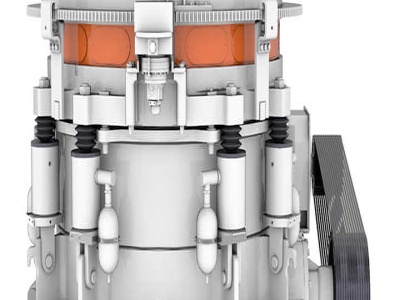

Construction, Working and ...

Crushing by compression is done between two surfaces, with the work being done by one or both surfaces. For example, jaw crushers using this method of compression are suitable for reducing extremely hard and abrasive rock. As a mechanical reduction method, compression should be used for the following. If the material is hard and tough.