Jaw Crusher Improvement | Crusher Blog

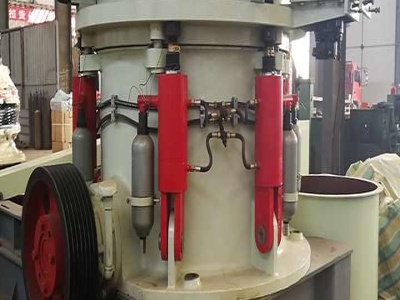

Aug 05, 2011 · PE400 × 600 Jaw crusher eccentric shaft taper bearing the original short life, although welllubried and sealed, but the general use of h bearing on the failure.. The inspection found that the bearing sleeve is mainly due to fragile parts will form a period of time as shown in Figure 1 (a) shows the ladder, has not been set tight on the shaft sleeve, the sleeve top end of the ...