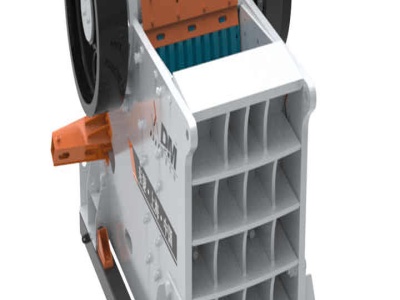

Silica Noise at a Rock Crusher | Industrial Hygiene in ...

Sep 01, 2010 · Silica Noise at a Rock Crusher. Industrial hygiene at a surfacemine rock crushing operation is primarily 2 major hazards: 1. airborne silica dust and 2. noise. (there are many more safety hazards but I will focus on IH) Silica – this can vary due to: the amount of silica in the rock, weather conditions, type of equipment, if water is used ...