Manufacturers of gold mining prospecting equipment

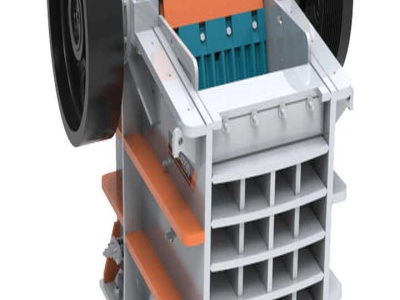

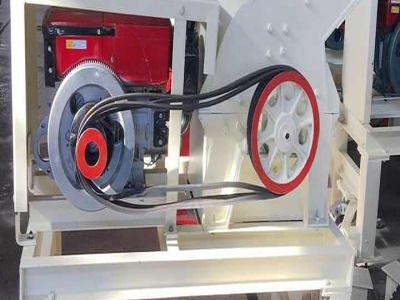

Ideal for areas that you can make mineral discoveries, but not allowed to run motorized equipment due to ecological laws or fire codes. It works great to crush your black sand concentrates for further extraction of fine gold. Made in the Manufacturer of the CrazyChrusher hand operated jaw crusher. Dahlke Dredge Mfg. 950 Snipes Pump Rd.