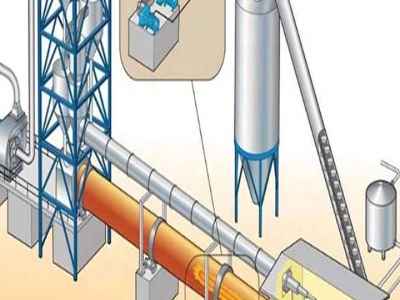

Kaolin mining techniques – rotary core, auger drilling methods

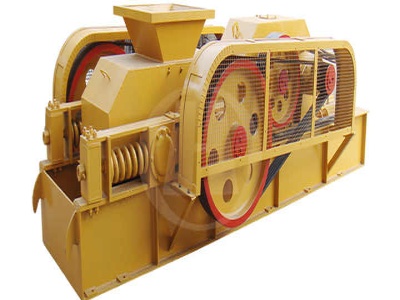

Mined out land is then used as a habitat for wildlife, timber plantations, farming, hunting and order to achieve the brightness or whiteness, flotation or selective flocculation is used to remove the color causing minerals. It is often caused by .