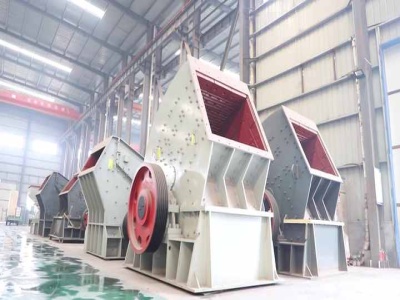

Impact Crusher Hematite Pakistan

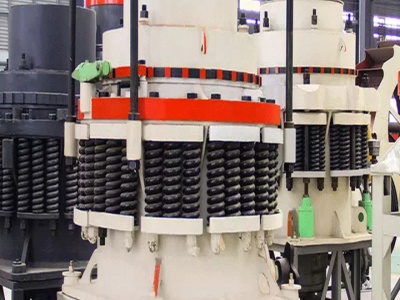

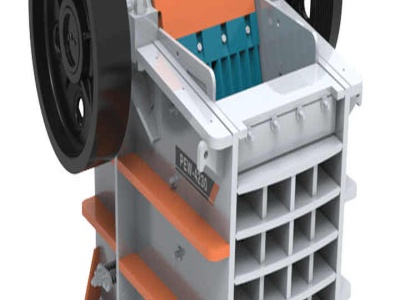

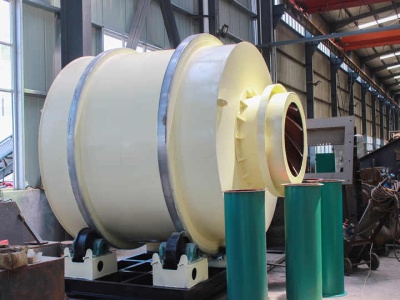

Jul 01, 2020 · Crusher hematite process. beneficiation process for hematite ore. . jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand. our product is widely used in mining,.