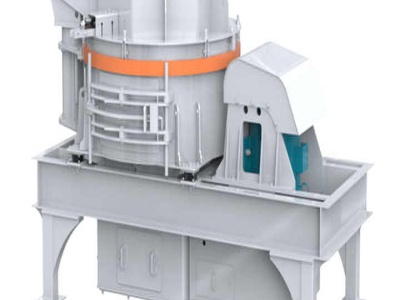

FOR VERTICAL ROLLER MILLS

and energy consumption compared to ball mills. Loesche GmbH, Germany, has been a leading supplier of roller mills for over 100 years and in more recent times, has expanded by adding a subsidiary automation company for both hardware and software delivery and project management. The latest addition to the automation