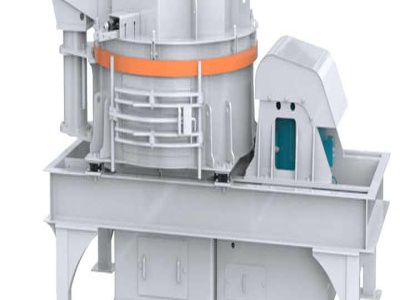

Wet Grid Ball Mill

The ball mill is composed of the main part such as a feeding part, a discharging part, a turning part, a transmission part (a reduction gear, a small transmission gear, a motor, and electric control). The hollow shaft is made of cast steel, the inner lining can be replaced, the rotary large gear is processed by casting hobbing, and the barrel ...