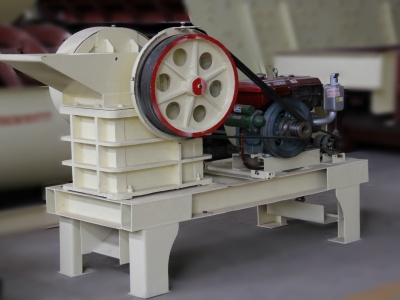

Primary Jaw Crusher Installation

The total cost of a jaw crusher installation, Centrals Scope of Works is the civil works associated with the installation of a new Primary Crusher . Prices / Quote. Primary Crusher Installation . Primary Crusher Installation. For Hanson Ltd, Penmaenmawr. Design Fabriion of support structure Installation 350,000 . More Information For more information on this, or any of our projects listed ...