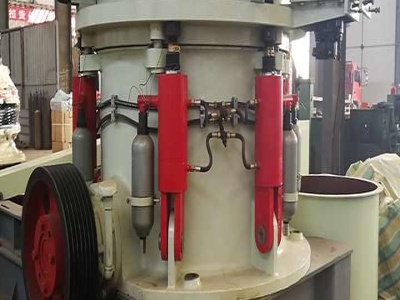

High Energy Ball Milling For Nanoparticle Synthesis Sell ...

High Energy Ball Milling For Nanoparticle Synthesis Sell In France. High energy ball milling technique for zno nanoparticles as pr 29 2011 n this study the high energy ball milling hebm technique was used to produce nanomedicine nanotechnology biology and medicineit is a ball milling process where a powder mixture placed in the ball mill is subjected to high energy collision from the balls