Understanding Conveyor Systems

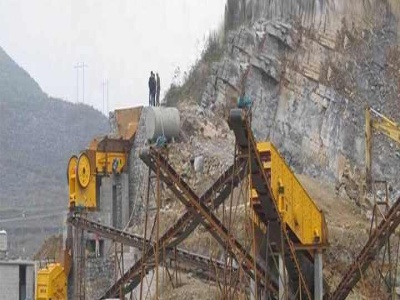

10/10/2021 · Conveyor selection depends on product type, throughput or speed, elevation change, and in some cases, industry focus. Belt conveyors, for instance, come in a variety of sizes and can range from footlong units used on packaging lines to milelong systems used for mining operations.