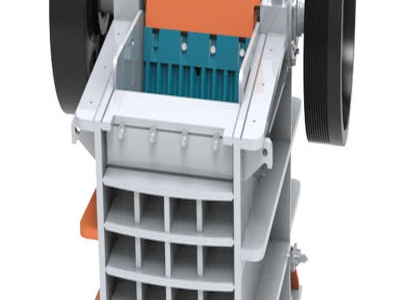

Jaw Crusher Working Principle

· · JAW CRUSHERS. Since the jaw crusher was pioneered by Eli Whitney Blake in the 2nd quarter of the 1800s, many have twisted the Patent and come up with other types of jaw crushers in hopes of crushing rocks and stones more effectively. Those 'other' types of jaw crusher inventors having given birth to 3 groups: Double Toggle of the Blake Type